Technical Information

Technical Information / Codes and Standards

Metal Building Energy Codes and Standards

Energy codes and minimum energy standards have become more and more relevant to designers, contractors and owners. Increases in stringency and more efficient alternatives have both pulled and pushed the way metal buildings are insulated. If you are new to energy codes or if your a seasoned codes and standards guru, we are confident that our information regarding metal buildings will serve as a value tool to meet and understand the energy code intent.

Energy codes and minimum energy standards have become more and more relevant to designers, contractors and owners. Increases in stringency and more efficient alternatives have both pulled and pushed the way metal buildings are insulated. If you are new to energy codes or if your a seasoned codes and standards guru, we are confident that our information regarding metal buildings will serve as a value tool to meet and understand the energy code intent.

Today's low rise commercial energy code minimums are based upon essentially two primary documents (model codes) and in vast majority of the time considered mandatory:

Model Codes

|

|

|

|---|---|---|

| Document |

ASHRAE Standard 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings |

IECC International Energy Conservation Code |

| Developed By | American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. ~ Atlanta, GA | International Code Council, Inc. ~ Washington, D.C. |

| Update cycle | Typically every 3 years | Typically every 3 years |

| Versions | 2016 2013 2010 2007 2004 2001 1999 1989 | 2018 2015 2012 2009 2006 2003 2000 1998 |

| Logos courtesy of ASHRAE and ICC | ||

METAL BUILDING ROOF & WALL - Classifications

| Roofs | Walls |

|---|---|

| Insulation Above Deck | Mass |

| Metal Buildings | Metal Building |

| Attic & Other | Steel Framed |

| Wood Framed |

For low rise commercial buildings, both the IECC and Standard 90.1 now utilize three different roof classifications and four different above grade wall classifications.

Each type of roof and wall classification has it's own set of minimum thermal envelope requirements and may vary from climate zone to climate zone and even conditioning needs. Those minimum thermal envelope requirements are determined and intended to be the U-factor of the insulation assembly, essentially a baseline (Budget U-factor) to meet or exceed.

Metal Building Insulation - Base Assemblies

Metal Building Roof

The 'base assembly' for a metal building roof has essentially been a single layer (pre-installed R-19) of metal building fiber glass insulation laminated with a vapor retarder. The fiber glass insulation is installed atop and perpendicular to the purlins and compressed when the metal roof sheet is attached. It includes a thermal spacer block placed above the compressed insulation and purlins which eludes to a standing seam roof vs. a thru-fastened (screw down roof).

Learn more about Traditional Methods ►

Metal Building Wall

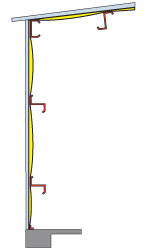

The 'base assembly' for a metal building wall has been a single layer (4” pre-installed R13) of metal building fiber glass insulation laminated with a vapor retarder. The fiber glass insulation is installed outside and perpendicular to the girts and compressed when the metal wall panel is attached.

Learn more about Traditional Methods ►

Newer and updated codes and standards have now increased stringency and requiring more than a single layer of compressed insulation for the metal building roof and walls.

Note: Fiberglass insulation that is compressed behind girts should NOT be considered 'continuous insulation' per the intent and definition within the Energy Code/Standard.

Prescriptive Requirements for metal buildings

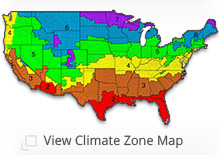

The prescriptive path is one method in order to determine mandatory compliance and is far and away the most popular compliance path for metal buildings. Recent and forthcoming versions of both 90.1 and IECC feature eight different climate zones based on a variety of factors including climate, heating and cooling needs. National code bodies utilize the climate zones in addition to other analysis tools to determine the minimum criteria of energy efficiency of the building thermal envelope such as windows, doors and of course insulation. For instance, the insulation minimums are different from Miami, FL compared to Fairbanks, AK. Keep in mind these are only minimum requirements to meet the energy code and should not be considered 'optimum' performance levels for the building. To determine the optimal level of insulation for your building,

run a EnergyCraft™ Design for your building.