Metal Building Energy Codes and Standards

Thermal Design has summarized and critiqued certain items within each listed code and standard. Differences in codes and standards vary from publication to publication, however the following information is specific and tailored for insulating pre-engineered metal buildings. It is your responsibility to check with any and all applicable codes that pertain to your projects to ensure the minimum energy code intent is met. If you have questions or would like additional information, please contact us.

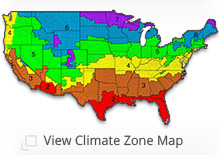

Key:

![]()

2018 IECC

Prescriptive tables

Table C402.1.3 Opaque Thermal Envelope Insulation Component Minimum Requirements, R-value Method (ALL OTHER CRITERIA)

Table C402.1.4 Opaque Thermal Envelope Assembly Maximum Requirements, U-factor Method (All Other CRITERIA)

| Climate Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

|

ASSEMBLY MAXIMUM U-Factor |

Roof | U-0.044 | U-0.035 | U-0.035 | U-0.035 | U-0.035 | U-0.031 | U-0.029 | U-0.029 |

| Wall | U-0.079 | U-0.079 | U-0.079 | U-0.052 | U-0.052 | U-0.052 | U-0.052 | U-0.052 | |

|

ASSEMBLY MINIMUM R-Value |

Roof |

|

R19+R11 LS | R19+R11 LS | R19+R11 LS | R19+R11 LS | R25+R11 LS | R30+R11 LS | R30+R11 LS |

| Wall | R13+R6.5ci | R13+R6.5ci | R13+R6.5ci | R13+R13ci | R13+R13ci | R13+R13ci | R13+R13ci | R13+R13ci | |

|

LS = Liner System ci = Continuous insulation |

|||||||||

![]() Screw down roof without thermal spacer block.

Screw down roof without thermal spacer block.

Assembly u-factors

Footnote 'a' in Table C402.1.4 allows the use of assembly U-factors from ASHRAE 90.1-2016, Appendix A, however the construction needs to comply with the applicable construction details from ASHRAE 90.1, Appendix A.

![]() The 2018 IECC does not feature a complete metal building roof and wall assembly list with corresponding installed performance values like ASHRAE Standard 90.1, however the assemblies performance values are from the ASHRAE 90.1-2016 Tables A2.3.3 (roofs) and A3.2.2 (walls) that recognizes and incorporates the revised U-factors for traditional assemblies.

The 2018 IECC does not feature a complete metal building roof and wall assembly list with corresponding installed performance values like ASHRAE Standard 90.1, however the assemblies performance values are from the ASHRAE 90.1-2016 Tables A2.3.3 (roofs) and A3.2.2 (walls) that recognizes and incorporates the revised U-factors for traditional assemblies.

Assembly Decriptions

Footnote 'a' in Table C402.1.3 Opaque Thermal Envelope Insulation Component Requirements states: Assembly descriptions can be found in ANSI/ASHRAE/IESNA Appendix A and applies to Metal Building roof as well as the entire table in general.

![]() The 2018 IECC is very limited in describing assemblies with the exception of a Liner System (LS), and relies upon the metal building descriptions from the reference document ASHRAE 90.1-2016.

The 2018 IECC is very limited in describing assemblies with the exception of a Liner System (LS), and relies upon the metal building descriptions from the reference document ASHRAE 90.1-2016.

LS = Liner System

Defines the liner system metal building roof assembly in Chapter 2 Definitions in the 2018 IECC.

1. a continuous vapor barrier liner membrane that is installed below the purlins and that is uninterrupted by framing members.

2. An uncompressed, unfaced insulation resting on top of the liner membrane and located betwen the purlins.

Footnote 'b' in Table C402.1.3 Opaque Thermal Envelope Insulation Component Minimum Requirements states: Where using R-value compliance method, a thermal spacer block shall be provided, otherwise use the U-factor compliance method in Table C402.1.4.

![]() Essentially a thermal spacer block is required with the R19+R11 liner system assembly for climate zones 2-8 base upon the corresponding U-factors outlined in Table C402.1.4. However as stated in the footnote, alternative assemblies may be considered using the U-factor compliance method.

Essentially a thermal spacer block is required with the R19+R11 liner system assembly for climate zones 2-8 base upon the corresponding U-factors outlined in Table C402.1.4. However as stated in the footnote, alternative assemblies may be considered using the U-factor compliance method.

90.1-2016

Prescriptive tables

5.5-0 thru 5.5-8, Metal Building Envelope Requirements (Nonresidential Criteria)

| Climate Zone | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|---|

|

ASSEMBLY MAXIMUM U-Factor |

Roof | U-0.041 | U-0.041 | U-0.041 | U-0.041 | U-0.037 | U-0.037 | U-0.031 | U-0.029 | U-0.026 |

| Wall | U-0.094 | U-0.094 | U-0.094 | U-0.094 | U-0.060 | U-0.050 | U-0.050 | U-0.044 | U-0.039 | |

|

ASSEMBLY MINIMUM R-Value |

Roof | R10+R19 FC | R10+R19 FC | R10+R19 FC | R10+R19 FC |

R19+R11 LS or R25+R8 LS |

R19+R11 LS or R25+R8 LS |

R25+R11 LS | R30+R11 LS | R25+R11+R11 LS |

| Wall | R0+R9.8ci | R0+R9.8ci | R0+R9.8ci | R0+R9.8ci | R0+R15.8ci | R0+R19.0ci | R0+R19.0ci | R0+R22.1ci | R0+R25.0ci | |

![]() The 90.1-2016 prescriptive requirements for metal building roof insulation assemblies are of the same stringency of 90.1-2013 prescriptive requirements; however 90.1-2016 has also added climate zone 0 (zero). Standard 90.1-2013 was the first 90.1 Standard that recognized and implemented the revised U-factors for metal building roof and wall insulation assemblies that were found to be overstated per ASHRAE news release (Jan 12, 2010). The revised U-factors are listed in 90.1-2016 Appendix Table A2.3.3 (roofs) and Table A3.2.3 (walls).

The 90.1-2016 prescriptive requirements for metal building roof insulation assemblies are of the same stringency of 90.1-2013 prescriptive requirements; however 90.1-2016 has also added climate zone 0 (zero). Standard 90.1-2013 was the first 90.1 Standard that recognized and implemented the revised U-factors for metal building roof and wall insulation assemblies that were found to be overstated per ASHRAE news release (Jan 12, 2010). The revised U-factors are listed in 90.1-2016 Appendix Table A2.3.3 (roofs) and Table A3.2.3 (walls).

![]() The metal building wall prescriptive R-value assemblies feature 'ci' continuous insulation assemblies. 90.1-2013 defines continuous insulation ('ci') as: insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope. Thus hanging fiberglass insulation from the eave, outside the girts, and compressed when the wall panels are attached should NOT be considered 'continuous insulation'; nor does filling the cavity space with uncompressed insulation between girts qualify for 'continuous insulation'.

The metal building wall prescriptive R-value assemblies feature 'ci' continuous insulation assemblies. 90.1-2013 defines continuous insulation ('ci') as: insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope. Thus hanging fiberglass insulation from the eave, outside the girts, and compressed when the wall panels are attached should NOT be considered 'continuous insulation'; nor does filling the cavity space with uncompressed insulation between girts qualify for 'continuous insulation'.

Assembly u-factors

Table A2.3.3, Assembly U-factors for Metal Building Roofs

Multiple R-values are listed in order from inside to outside.

R3 thermal spacer blocks are incorporated with all assemblies which reference use of a thermal spacer block with one exception; the Filled Cavity (FC) assembly lists a R5 thermal spacer block for the standing seam roof.

Standing Seam Roof with Thermal Spacer Blocks

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

|---|---|---|---|

|

Single Layer |

|||

| R-10 | U-0.115 | R-8.7 | |

| R-11 | U-0.107 | R-9.3 | |

| R-13 | U-0.101 | R-9.9 | |

| R-16 | U-0.096 | R-10.4 | |

| R-19 | U-0.082 | R-12.2 | |

|

Double Layer |

R10 + R10 | U-0.088 | R-11.4 |

| R11 + R10 | U-0.086 | R-11.6 | |

| R11 + R11 | U-0.085 | R-11.8 | |

| R13 + R10 | U-0.084 | R-11.9 | |

| R13 + R11 | U-0.082 | R-12.2 | |

| R13 + R13 | U-0.075 | R-13.3 | |

| R19 + R10 | U-0.074 | R-13.5 | |

| R19 + R11 | U-0.072 | R13.9 | |

| R19 + R13 | U-0.068 | R-14.7 | |

| R19 + R16 | U-0.065 | R-15.4 | |

| R19 + R19 | U-0.060 | R-16.7 | |

|

Liner System |

R19 + R11 | U-0.037 | R-27.0 |

| R25 + R8 | U-0.037 | R-27.0 | |

| R25 + R11 | U-0.031 | R-32.3 | |

| R30 + R11 | U-0.029 | R-34.5 | |

| R25+R11+ R11 | U-0.026 | R-38.5 | |

| Filled Cavity | R10 + R19 | U-0.041 | R-24.4 |

Standing Seam Roof without Thermal spacer blocks

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

|---|---|---|---|

| Liner System | R19 + R11 | U-0.040 | R-25.0 |

through-Fastened Roof without Thermal Spacer Blocks

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

|---|---|---|---|

|

Single Layer |

R-10 | U-0.184 | R-5.4 |

| R-11 | U-0.182 | R-5.5 | |

| R-13 | U-0.174 | R-5.7 | |

| R-16 | U-0.157 | R-6.4 | |

| R-19 | U-0.151 | R-6.6 |

Table A3.2.3, Assembly U-factors for Metal Building Walls

Multiple R-values are listed in order from inside to outside.

- A minimum of R-0.375 thermal spacer block or thermal break strip is required when installed without continuous insulation.

- A minimum of R-0.75 thermal spacer block or thermal break strip is required when installed without continuous insulation.

- A minimum R-3 thermal spacer block required.

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

|---|---|---|---|

|

Single Layer |

|||

| R-10 | U-0.186 | R-5.4 | |

| R-11 | U-0.185 | R-5.4 | |

| R-13 | U-0.162 | R-6.2 | |

| R-16 | U-0.155 | R-6.5 | |

| R-19 | U-0.147 | R-6.8 | |

| Single Layer in cavity | R-25a | U-0.059 | R-16.9 |

| R-30b | U-0.052 | R-19.2 | |

|

Double Layer |

|||

| R-25+R-10 | U-0.047 | R-21.3 | |

| R-25+R-16 | U-0.042 | R-23.8 | |

| R-25+R-10c | U-0.039 | R-25.6 | |

| R-30+R-16 | U-0.039 | R-25.6 | |

Metal Building Assembly descriptions

Appendix A

Metal Building Roofs (A2.3)

Describes the metal building roof base assembly as a roof with a thermal spacer block and the insulation is draped perpendicular over the purlins and compressed when the metal roof sheets are installed. It is noted that purlins are spaced nominally 5' on center.

Single Layer (A2.3.2.1)

Refers to a single layer metal building insulation that is laminated with a vapor retarder and is draped perpendicular over purlins and compressed when the roof sheets are attached. Minimum R-3 thermal spacer block required when specified in the assembly table A2.3.3.

![]() Typically known in the metal building industry as 'Over-the-Purlin' method. Learn more about Traditional Methods

Typically known in the metal building industry as 'Over-the-Purlin' method. Learn more about Traditional Methods

Double Layer (A2.3.2.2)

Refers to the second layer of metal building insulation which is unfaced and installed parallel to the purlins and placed on top of the first 'single layer'. Minimum R-3 thermal spacer block required when specified in the assembly table A2.3.3.

![]() This assembly is typically known in the metal building industry as a 'Sag and Bag' method. Although this method features two layers of fiberglass, both layers are still severely compressed and restricted by purlin bracing. Learn more about Traditional Methods

This assembly is typically known in the metal building industry as a 'Sag and Bag' method. Although this method features two layers of fiberglass, both layers are still severely compressed and restricted by purlin bracing. Learn more about Traditional Methods

Continuous Insulation (A2.3.2.3)

Refers to insulation which is installed above or below the purlins, uncompressed and uninterrupted by framing members.

Continuous Insulation (c.i.) (Section 3, Definitions)

Refers to insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope.

![]() Metal building fiberglass insulation which is compressed does not constitute as 'continuous insulation', nor does fiberglass insulation filled within the cavity and interrupted by purlins.

Metal building fiberglass insulation which is compressed does not constitute as 'continuous insulation', nor does fiberglass insulation filled within the cavity and interrupted by purlins.

Liner System (Ls) (A2.3.2.4)

Refers to an assembly with the a continuous vapor retarder/membrane that is installed below the purlins and uninterrupted by framing members. Unfaced and uncompressed metal building insulation rests on top of the membrane/liner and is installed parallel between the purlins. Multilayer installations, the last rated Rvalue is for unfaced insulation draped perpendicular over purlins and then compressed when the metal roof sheets are installed. Minimum R-3 thermal spacer block required when specified in the assembly table A2.3.3.

![]() All liner systems listed in 90.1-2013 are multilayer. Most are two layer assemblies with the thicker layer of insulation installed parallel between the purlins and the thin layer is draped perpendicular over the purlin. However, it's important to note that the Standard also lists a three layer Liner system assembly (R25+R11+R11 Ls) in which two layers of uncompressed, unfaced insulation are both installed parallel, between purlins and the thin layer draped perpendicular over the purlin. The Simple Saver System meets the description of the described Liner System. Learn more

All liner systems listed in 90.1-2013 are multilayer. Most are two layer assemblies with the thicker layer of insulation installed parallel between the purlins and the thin layer is draped perpendicular over the purlin. However, it's important to note that the Standard also lists a three layer Liner system assembly (R25+R11+R11 Ls) in which two layers of uncompressed, unfaced insulation are both installed parallel, between purlins and the thin layer draped perpendicular over the purlin. The Simple Saver System meets the description of the described Liner System. Learn more

Liner System (Ls) (Section 3, Definitions)

Refers to an assembly that features a continuous vapor barrier liner installed below the purlins and uninterrupted by framing members.

Metal Building Walls (A3.2)

Describes the metal building wall base assembly as a wall with metal wall panels and a metal structure. Exposed insulation to a conditioned or semi heated space requires a facing with seams overlapped and sealed. Noted that default U-factors in tables are provided for average girt spacing at least of 52".

Single Layer Compressed (A3.2.2.1)

Refers to a single layer of metal building insulation that is laminated with a vapor retarder and is compressed between panels and steel structure.

![]() Typically known in the metal building industry as 'Behind-the-Girt' method. The fiberglass insulation is vertically hung at the top and outside of the building, perpendicular to the girts. The fiberglass insulation is compressed throughout the girt space and severely compressed at the girt/panel fastening point when the metal wall panels are attached. Learn more about Traditional Methods

Typically known in the metal building industry as 'Behind-the-Girt' method. The fiberglass insulation is vertically hung at the top and outside of the building, perpendicular to the girts. The fiberglass insulation is compressed throughout the girt space and severely compressed at the girt/panel fastening point when the metal wall panels are attached. Learn more about Traditional Methods

Continuous Insulation (A2.3.2.2)

Refers to insulation that is continuous and is installed on the outside or inside the girts, uncompressed and uninterrupted by the framing members.

Continuous Insulation (c.i.) (Section 3, Definitions)

Refers to insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope.

![]() Metal building fiberglass insulation which is compressed does not constitute as 'continuous insulation', nor does fiberglass insulation filled within the cavity and interrupted by girts.

Metal building fiberglass insulation which is compressed does not constitute as 'continuous insulation', nor does fiberglass insulation filled within the cavity and interrupted by girts.

Single Layer in Cavity (A3.2.2.3)

Refers to uncompressed insulation installed in the cavity between the girts. A membrane or facing is installed inside of the girts to form a continuous layer. A thermal spacer block or thermal break strip between the girts and metal wall panel is required when specified in the assembly table A3.2.3

![]() Typically known in the industry as a liner system wall. Learn more about Simple Saver System wall.

Typically known in the industry as a liner system wall. Learn more about Simple Saver System wall.

Double Layer (A3.2.2.4)

Refers to the first rated R-value of insulation installed in the cavity between the girts. The second rated R-value is for compressed insualtion between metal wall panel in the steel structure.

A membrane or facing is installed inside of the girts to form a continuous layer. A thermal spacer block or thermal break strip between the girts and metal wall panel is required when specified in the assembly table A3.2.3

![]() Typically known in the industry as a liner system wall. Learn more about Simple Saver System wall.

Typically known in the industry as a liner system wall. Learn more about Simple Saver System wall.

2015 IECC

Prescriptive tables

Table C402.1.3 Opaque Thermal Envelope Insulation Component Minimum Requirements, R-value Method (ALL OTHER CRITERIA)

Table C402.1.4 Opaque Thermal Envelope Assembly Maximum Requirements, U-factor Method (All Other CRITERIA)

| Climate Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

|

ASSEMBLY MAXIMUM U-Factor |

Roof | U-0.044 | U-0.035 | U-0.035 | U-0.035 | U-0.035 | U-0.031 | U-0.029 | U-0.029 |

| Wall | U-0.079 | U-0.079 | U-0.079 | U-0.052 | U-0.052 | U-0.052 | U-0.052 | U-0.052 | |

|

ASSEMBLY MINIMUM R-Value |

Roof |

|

R19+R11 LS | R19+R11 LS | R19+R11 LS | R19+R11 LS | R25+R11 LS | R30+R11 LS | R30+R11 LS |

| Wall | R13+R6.5ci | R13+R6.5ci | R13+R6.5ci | R13+R13ci | R13+R13ci | R13+R13ci | R13+R13ci | R13+R13ci | |

|

LS = Liner System ci = Continuous insulation |

|||||||||

![]() Screw down roof without thermal spacer block.

Screw down roof without thermal spacer block.

Assembly u-factors

Footnote 'a' in Table C402.1.4 allows the use of assembly U-factors from ASHRAE 90.1-2013, Appendix A, however the construction needs to comply with the applicable construction details from ASHRAE 90.1, Appendix A.

![]() The 2015 IECC does not feature a complete metal building roof and wall assembly list with corresponding installed performance values like ASHRAE Standard 90.1, however the assemblies performance values are from the ASHRAE 90.1-2013 Tables A2.3.3 (roofs) and A3.2.2 (walls) that recognizes and incorporates the revised U-factors for traditional assemblies.

The 2015 IECC does not feature a complete metal building roof and wall assembly list with corresponding installed performance values like ASHRAE Standard 90.1, however the assemblies performance values are from the ASHRAE 90.1-2013 Tables A2.3.3 (roofs) and A3.2.2 (walls) that recognizes and incorporates the revised U-factors for traditional assemblies.

Assembly Decriptions

Footnote 'a' in Table C402.1.3 Opaque Thermal Envelope Insulation Component Requirements states: Assembly descriptions can be found in ANSI/ASHRAE/IESNA Appendix A and applies to Metal Building roof as well as the entire table in general.

![]() The 2015 IECC is very limited in describing assemblies with the exception of a Liner System (LS), and relies upon the metal building descriptions from the reference document ASHRAE 90.1-2013.

The 2015 IECC is very limited in describing assemblies with the exception of a Liner System (LS), and relies upon the metal building descriptions from the reference document ASHRAE 90.1-2013.

LS = Liner System

Defines the liner system metal building roof assembly in Chapter 2 Definitions in the 2015 IECC.

1. a continuous vapor barrier liner membrane that is installed below the purlins and that is uninterrupted by framing members.

2. An uncompressed, unfaced insulation resting on top of the liner membrane and located betwen the purlins.

Footnote 'b' in Table C402.1.3 Opaque Thermal Envelope Insulation Component Minimum Requirements states: Where using R-value compliance method, a thermal spacer block shall be provided, otherwise use the U-factor compliance method in Table C402.1.4.

![]() Essentially a thermal spacer block is required with the R19+R11 liner system assembly for climate zones 2-8 base upon the corresponding U-factors outlined in Table C402.1.4. However as stated in the footnote, alternative assemblies may be considered using the U-factor compliance method.

Essentially a thermal spacer block is required with the R19+R11 liner system assembly for climate zones 2-8 base upon the corresponding U-factors outlined in Table C402.1.4. However as stated in the footnote, alternative assemblies may be considered using the U-factor compliance method.

90.1-2013

Prescriptive tables

5.5-1 thru 5.5-8, Metal Building Envelope Requirements (Nonresidential Criteria)

| Climate Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

|

ASSEMBLY MAXIMUM U-Factor |

Roof | U-0.041 | U-0.041 | U-0.041 | U-0.037 | U-0.037 | U-0.031 | U-0.029 | U-0.026 |

| Wall | U-0.094 | U-0.094 | U-0.094 | U-0.060 | U-0.050 | U-0.050 | U-0.044 | U-0.039 | |

|

ASSEMBLY MINIMUM R-Value |

Roof | R10+R19 FC | R10+R19 FC | R10+R19 FC |

R19+R11 LS or R25+R8 LS |

R19+R11 LS or R25+R8 LS |

R25+R11 LS | R30+R11 LS | R25+R11+R11 LS |

| Wall | R0+R9.8ci | R0+R9.8ci | R0+R9.8ci | R0+R15.8ci | R0+R19.0ci | R0+R19.0ci | R0+R22.1ci | R0+R25.0ci | |

![]() The 90.1-2013 prescriptive requirements for metal building roof insulation assemblies are more stringent than past versions of the 90.1 Standard prescriptive requirements. 90.1-2013 Standard is the first 90.1 Standard that recognizes and implements the revised U-factors for metal building roof and wall insulation assemblies that were found to be overstated per ASHRAE news release (Jan 12, 2010). The revised U-factors are listed in Appendix Table A2.3.3 (roofs) and Table A3.2.3 (walls).

The 90.1-2013 prescriptive requirements for metal building roof insulation assemblies are more stringent than past versions of the 90.1 Standard prescriptive requirements. 90.1-2013 Standard is the first 90.1 Standard that recognizes and implements the revised U-factors for metal building roof and wall insulation assemblies that were found to be overstated per ASHRAE news release (Jan 12, 2010). The revised U-factors are listed in Appendix Table A2.3.3 (roofs) and Table A3.2.3 (walls).

![]() The metal building wall prescriptive R-value assemblies feature 'ci' continuous insulation assemblies. 90.1-2013 defines continuous insulation ('ci') as: insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope. Thus hanging fiberglass insulation from the eave, outside the girts, and compressed when the wall panels are attached should NOT be considered 'continuous insulation'; nor does filling the cavity space with uncompressed insulation between girts qualify for 'continuous insulation'.

The metal building wall prescriptive R-value assemblies feature 'ci' continuous insulation assemblies. 90.1-2013 defines continuous insulation ('ci') as: insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope. Thus hanging fiberglass insulation from the eave, outside the girts, and compressed when the wall panels are attached should NOT be considered 'continuous insulation'; nor does filling the cavity space with uncompressed insulation between girts qualify for 'continuous insulation'.

Assembly u-factors

Table A2.3.3, Assembly U-factors for Metal Building Roofs

Multiple R-values are listed in order from inside to outside.

R3 thermal spacer blocks are incorporated with all assemblies which reference use of a thermal spacer block with one exception; the Filled Cavity (FC) assembly lists a R5 thermal spacer block for the standing seam roof.

Standing Seam Roof with Thermal Spacer Blocks

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

|---|---|---|---|

|

Single Layer |

|||

| R-10 | U-0.115 | R-8.7 | |

| R-11 | U-0.107 | R-9.3 | |

| R-13 | U-0.101 | R-9.9 | |

| R-16 | U-0.096 | R-10.4 | |

| R-19 | U-0.082 | R-12.2 | |

|

Double Layer |

R10 + R10 | U-0.088 | R-11.4 |

| R11 + R10 | U-0.086 | R-11.6 | |

| R11 + R11 | U-0.085 | R-11.8 | |

| R13 + R10 | U-0.084 | R-11.9 | |

| R13 + R11 | U-0.082 | R-12.2 | |

| R13 + R13 | U-0.075 | R-13.3 | |

| R19 + R10 | U-0.074 | R-13.5 | |

| R19 + R11 | U-0.072 | R13.9 | |

| R19 + R13 | U-0.068 | R-14.7 | |

| R19 + R16 | U-0.065 | R-15.4 | |

| R19 + R19 | U-0.060 | R-16.7 | |

|

Liner System |

R19 + R11 | U-0.037 | R-27.0 |

| R25 + R8 | U-0.037 | R-27.0 | |

| R25 + R11 | U-0.031 | R-32.3 | |

| R30 + R11 | U-0.029 | R-34.5 | |

| R25+R11+ R11 | U-0.026 | R-38.5 | |

| Filled Cavity | R10 + R19 | U-0.041 | R-24.4 |

Standing Seam Roof without Thermal Block Spacers

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

|---|---|---|---|

| Liner System | R19 + R11 | U-0.040 | R-25.0 |

Through-Fastened Roof without Thermal Spacer Blocks

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

|---|---|---|---|

|

Single Layer |

R-10 | U-0.184 | R-5.4 |

| R-11 | U-0.182 | R-5.5 | |

| R-13 | U-0.174 | R-5.7 | |

| R-16 | U-0.157 | R-6.4 | |

| R-19 | U-0.151 | R-6.6 | |

| Liner System | R19 + R11 | U-0.044 | R-22.7 |

Table A3.2.3, Assembly U-factors for Metal Building Walls

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

|---|---|---|---|

|

Single Layer |

|||

| R-10 | U-0.186 | R-5.4 | |

| R-11 | U-0.185 | R-5.4 | |

| R-13 | U-0.162 | R-6.2 | |

| R-16 | U-0.155 | R-6.5 | |

| R-19 | U-0.147 | R-6.8 |

Metal Building Assembly descriptions

Appendix A

Metal Building Roofs (A2.3)

Describes the metal building roof base assembly as a roof with a thermal spacer block and the insulation is draped perpendicular over the purlins and compressed when the metal roof sheets are installed. It is noted that purlins are spaced nominally 5' on center.

Single Layer (A2.3.2.1)

Refers to a single layer metal building insulation that is laminated with a vapor retarder and is draped perpendicular over purlins and compressed when the roof sheets are attached. Minimum R-3 thermal spacer block required when specified in the assembly table A2.3.3.

![]() Typically known in the metal building industry as 'Over-the-Purlin' method. Learn more about Traditional Methods

Typically known in the metal building industry as 'Over-the-Purlin' method. Learn more about Traditional Methods

Double Layer (A2.3.2.2)

Refers to the second layer of metal building insulation which is unfaced and installed parallel to the purlins and placed on top of the first 'single layer'. Minimum R-3 thermal spacer block required when specified in the assembly table A2.3.3.

![]() This assembly is typically known in the metal building industry as a 'Sag and Bag' method. Although this method features two layers of fiberglass, both layers are still severely compressed and restricted by purlin bracing. Learn more about Traditional Methods

This assembly is typically known in the metal building industry as a 'Sag and Bag' method. Although this method features two layers of fiberglass, both layers are still severely compressed and restricted by purlin bracing. Learn more about Traditional Methods

Continuous Insulation (A2.3.2.2)

Refers to insulation which is installed above or below the purlins, uncompressed and uninterrupted by framing members.

Continuous Insulation (c.i.) (Section 3, Definitions)

Refers to insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope.

![]() Metal building fiberglass insulation which is compressed does not constitute as 'continuous insulation', nor does fiberglass insulation filled within the cavity and interrupted by purlins.

Metal building fiberglass insulation which is compressed does not constitute as 'continuous insulation', nor does fiberglass insulation filled within the cavity and interrupted by purlins.

Liner System (Ls) (A2.3.2.4)

Refers to an assembly with the a continuous vapor retarder/membrane that is installed below the purlins and uninterrupted by framing members. Unfaced and uncompressed metal building insulation rests on top of the membrane/liner and is installed parallel between the purlins. Multilayer installations, the last rated Rvalue is for unfaced insulation draped perpendicular over purlins and then compressed when the metal roof sheets are installed. Minimum R-3 thermal spacer block required when specified in the assembly table A2.3.3.

![]() All liner systems listed in 90.1-2013 are multilayer. Most are two layer assemblies with the thicker layer of insulation installed parallel between the purlins and the thin layer is draped perpendicular over the purlin. However, it's important to note that the Standard also lists a three layer Liner system assembly (R25+R11+R11 Ls) in which two layers of uncompressed, unfaced insulation are both installed parallel, between purlins and the thin layer draped perpendicular over the purlin. The Simple Saver System meets the description of the described Liner System. Learn more

All liner systems listed in 90.1-2013 are multilayer. Most are two layer assemblies with the thicker layer of insulation installed parallel between the purlins and the thin layer is draped perpendicular over the purlin. However, it's important to note that the Standard also lists a three layer Liner system assembly (R25+R11+R11 Ls) in which two layers of uncompressed, unfaced insulation are both installed parallel, between purlins and the thin layer draped perpendicular over the purlin. The Simple Saver System meets the description of the described Liner System. Learn more

Liner System (Ls) (Section 3, Definitions)

Refers to an assembly that features a continuous vapor barrier liner installed below the purlins and uninterrupted by framing members.

![]() A more detailed description of a liner system is found in Appendix A. (see A2.3.2.4)

A more detailed description of a liner system is found in Appendix A. (see A2.3.2.4)

Metal Building Walls (A3.2)

Describes the metal building wall base assembly as a wall with metal building insulation compressed between the metal wall panels and the girts. Additional wall assemblies include continuous insulation, uncompressed and uninterrupted by framing. Exposed insulation requires a facing and all seams are to be sealed to provide a continuous air barrier. Noted that default U-factors in tables are provided for average girt spacing at least of 52".

Single Layer (A3.2.2.1)

Refers to a single layer of metal building insulation that is laminated with a vapor retarder and is compressed between panels and steel structure.

![]() Typically known in the metal building industry as 'Behind-the-Girt' method. The fiberglass insulation is vertically hung at the top and outside of the building, perpendicular to the girts. The fiberglass insulation is compressed throughout the girt space and severely compressed at the girt/panel fastening point when the metal wall panels are attached. Learn more about Traditional Methods

Typically known in the metal building industry as 'Behind-the-Girt' method. The fiberglass insulation is vertically hung at the top and outside of the building, perpendicular to the girts. The fiberglass insulation is compressed throughout the girt space and severely compressed at the girt/panel fastening point when the metal wall panels are attached. Learn more about Traditional Methods

Continuous Insulation (A2.3.2.2)

Refers to insulation that is continuous and is installed on the outside or inside the girts, uncompressed and uninterrupted by the framing members.

Continuous Insulation (c.i.) (Section 3, Definitions)

Refers to insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope.

![]() Metal building fiberglass insulation which is compressed does not constitute as 'continuous insulation', nor does fiberglass insulation filled within the cavity and interrupted by girts.

Metal building fiberglass insulation which is compressed does not constitute as 'continuous insulation', nor does fiberglass insulation filled within the cavity and interrupted by girts.

2012 IECC

Prescriptive tables

Table C402.1.2, Opaque Thermal Envelope Assembly Requirements (ALL OTHER CRITERIA)

Table c402.2, Opaque thermal Envelope Requirements (All Other CRITERIA)

| Climate Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

|

ASSEMBLY MAXIMUM U-Factor |

Roof | U-0.044 | U-0.035 | U-0.035 | U-0.035 | U-0.035 | U-0.031 | U-0.029 | U-0.029 |

| Wall | U-0.079 | U-0.079 | U-0.079 | U-0.052 | U-0.052 | U-0.052 | U-0.052 | U-0.052 | |

|

ASSEMBLY MINIMUM R-Value |

Roof | R19+R11 LS | R19+R11 LS | R19+R11 LS | R19+R11 LS | R19+R11 LS | R25+R11 LS | R30+R11 LS | R30+R11 LS |

| Wall | R13+R6.5ci | R13+R6.5ci | R13+R6.5ci | R13+R13ci | R13+R13ci | R13+R13ci | R13+R13ci | R13+R13ci | |

|

LS = Liner System ci = Continuous insulation |

|||||||||

Assembly u-factors

Footnote 'a' in Table C402.1.2 allows the use of assembly U-factors from ASHRAE 90.1-2010, Appendix A, however the construction needs to comply with the applicable construction details from ASHRAE 90.1, Appendix A.

![]() The 2012 IECC does not feature a complete metal building roof and wall assembly list with corresponding installed performance values like ASHRAE Standard 90.1, however the assemblies performance values are from the upcoming ASHRAE 90.1 Tables A2.3 (roofs) and A3.2 (walls) that recognizes and incorporates the revised U-factors for traditional assemblies.

The 2012 IECC does not feature a complete metal building roof and wall assembly list with corresponding installed performance values like ASHRAE Standard 90.1, however the assemblies performance values are from the upcoming ASHRAE 90.1 Tables A2.3 (roofs) and A3.2 (walls) that recognizes and incorporates the revised U-factors for traditional assemblies.

Assembly Decriptions

Footnote 'a' in Table C402.2 Opaque Thermal Envelope Requirements states: Assembly descriptions can be found in ANSI/ASHRAE/IESNA Appendix A and applies to Metal Building roof as well as the entire table in general.

![]() The 2012 IECC is very limited in describing assemblies with the exception of a Liner System (LS), and relies upon the metal building descriptions from the reference document ASHRAE 90.1-2010.

The 2012 IECC is very limited in describing assemblies with the exception of a Liner System (LS), and relies upon the metal building descriptions from the reference document ASHRAE 90.1-2010.

LS = Liner System

Describes the liner system metal building roof assembly beneath Table C402.2 Opaque Thermal Envelope Requirements as a continuous membrane installed below the purlins and uninterrupted by framing members. Uncompressed, unfaced insulation rests on top of the membrane between the purlins.

![]() The description for the liner system assembly could provide more detail in terms of the specific insulation reference, such as 90.1-2010's description. Whereas the unfaced and uncompressed metal building insulation rests on top of the membrane/liner and is installed parallel between the purlins. Multilayer installations, the first rated R-value is for unfaced insulation draped perpendicular over purlins and then compressed when the metal roof sheets are installed.

The description for the liner system assembly could provide more detail in terms of the specific insulation reference, such as 90.1-2010's description. Whereas the unfaced and uncompressed metal building insulation rests on top of the membrane/liner and is installed parallel between the purlins. Multilayer installations, the first rated R-value is for unfaced insulation draped perpendicular over purlins and then compressed when the metal roof sheets are installed.

Footnote 'b' in Table C402.2 Opaque Thermal Envelope Requirements states: Where using R-value compliance method, a thermal spacer block shall be provided, otherwise use the U-factor compliance method in Table C402.1.2. This footnote specifically applies to Metal Building roofs (with R-5 thermal blocks).

![]() Essentially a thermal spacer block is required with the R19+R11 liner system assembly for climate zones 2-8 base upon the corresponding U-factors outlined in Table C402.1.2. However as stated in the footnote, alternative assemblies may be considered using the U-factor compliance method.

Essentially a thermal spacer block is required with the R19+R11 liner system assembly for climate zones 2-8 base upon the corresponding U-factors outlined in Table C402.1.2. However as stated in the footnote, alternative assemblies may be considered using the U-factor compliance method.

90.1-2010

Prescriptive tables

5.5-1 thru 5.5-8, Metal Building Envelope Requirements (NONRESIDENTIAL CRITERIA)

| Climate Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

|

ASSEMBLY MAXIMUM U-Factor |

Roof | U-0.065 | U-0.055 | U-0.055 | U-0.055 | U-0.055 | U-0.049 | U-0.049 | U-0.035 |

| Wall | U-0.093 | U-0.093 | U-0.084 | U-0.084 | U-0.069 | U-0.069 | U-0.057 | U-0.057 | |

|

ASSEMBLY MINIMUM R-Value |

Roof | R19 | R13+R13 | R13+R13 | R13+R13 | R13+R13 | R13+R19 | R13+R19 | R11+R19 LS |

| Wall | R16 | R16 | R19 | R19 | R13+R5.6ci | R13+R5.6ci | R19+R5.6ci | R19+R5.6ci | |

![]() WARNING! Listed R-value metal building roof and wall assemblies do not perform as the corresponding published U-factor as typically installed. Differences (OLD/NEW) are shown below in Table A2.3 and Table A3.2. Further background information can be viewed: ASHRAE Press Release (Jan 12, 2010)

WARNING! Listed R-value metal building roof and wall assemblies do not perform as the corresponding published U-factor as typically installed. Differences (OLD/NEW) are shown below in Table A2.3 and Table A3.2. Further background information can be viewed: ASHRAE Press Release (Jan 12, 2010)

![]() The metal building wall U-factors associated with 'hybrid' R-value assemblies feature both fiberglass insulation and continuous insulation are skeptical in the manner it is described in the Standard and in the manner it's “calculated”. The associated U-factor for the hybrid assemblies is calculated by using the U-factor for the installed fiberglass insulation and converting it to the installed R-value (example: Pre-installed R-13 = U-0.113 = Installed R-8.8). The installed R-value of the fiberglass insulation is added to the R-value of the ci increment (R-8.8 + R-5.6ci = R-14.4), then divided by 1 to represent the 'calculated' U-factor of the assembly (1/ R-14.4 = U-0.069).

The metal building wall U-factors associated with 'hybrid' R-value assemblies feature both fiberglass insulation and continuous insulation are skeptical in the manner it is described in the Standard and in the manner it's “calculated”. The associated U-factor for the hybrid assemblies is calculated by using the U-factor for the installed fiberglass insulation and converting it to the installed R-value (example: Pre-installed R-13 = U-0.113 = Installed R-8.8). The installed R-value of the fiberglass insulation is added to the R-value of the ci increment (R-8.8 + R-5.6ci = R-14.4), then divided by 1 to represent the 'calculated' U-factor of the assembly (1/ R-14.4 = U-0.069).

Assembly u-factors

Table A2.3, Assembly U-factors for Metal Building Roofs

Standing Seam Roof with Thermal Spacer Blocks

Overstated

20.7%

Climate Zone

1

Overstated

26.7%

Climate Zone

2 - 5

Overstated

27.9%

Climate Zone

6 - 7

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

Overstated | |

|---|---|---|---|---|---|

|

Single Layer |

R-6 | old | U-0.167 | R-5.9 | N/A |

| new | N/A | N/A | |||

| R-10 | old | U-0.097 | R-10.3 | 15.7% | |

| new | U-0.115 | R-8.7 | |||

| R-11 | old | U-0.092 | R-10.8 | 14.0% | |

| new | U-0.107 | R-9.3 | |||

| R-13 | old | U-0.083 | R-12.0 | 17.8% | |

| new | U-0.101 | R-9.9 | |||

| R-16 | old | U-0.072 | R-13.9 | 25.0% | |

| new | U-0.096 | R-10.4 | |||

| R-19 | old | U-0.065 | R-15.4 | 20.7% | |

| new | U-0.082 | R-12.2 | |||

|

Double Layer |

R10 + R10 | old | U-0.063 | R-15.8 | 28.4% |

| new | U-0.088 | R-11.4 | |||

| R10 + R11 | old | U-0.061 | R-16.4 | 29.1% | |

| new | U-0.086 | R-11.6 | |||

| R11 + R11 | old | U-0.060 | R-16.6 | 29.4% | |

| new | U-0.085 | R-11.8 | |||

| R10 + R13 | old | U-0.058 | R-17.2 | 31.0% | |

| new | U-0.084 | R-11.9 | |||

| R11 + R13 | old | U-0.057 | R-17.5 | 30.5% | |

| new | U-0.082 | R-12.2 | |||

| R13 + R13 | old | U-0.055 | R-18.1 | 26.7% | |

| new | U-0.075 | R-13.3 | |||

| R10 + R19 | old | U-0.052 | R-19.2 | 29.7% | |

| new | U-0.074 | R-13.5 | |||

| R11 + R19 | old | U-0.051 | R-19.6 | 29.2% | |

| new | U-0.072 | R13.9 | |||

| R13 + R19 | old | U-0.049 | R-20.4 | 27.9% | |

| new | U-0.068 | R-14.7 | |||

| R16 + R19 | old | U-0.047 | R-21.2 | 27.7% | |

| new | U-0.065 | R-15.4 | |||

| R19 + R19 | old | U-0.046 | R-21.7 | 23.3% | |

| new | U-0.060 | R-16.7 | |||

|

Liner System |

R11 + R19 | U-0.035 | R-28.6 | N/A | |

| R11 + R25 | U-0.031 | R-32.3 | N/A | ||

| R11 + R30 | U-0.029 | R-34.5 | N/A | ||

| R11+R11+ R25 | U-0.026 | R-38.5 | N/A | ||

| Filled Cavity | R19 + R10 | U-0.041 | R-24.4 | N/A |

Standing Seam Roof without Thermal Block Spacers

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

Overstated |

|---|---|---|---|---|

| Liner System | R11 + R19 | U-0.040 | R-25.0 | N/A |

Thru-Fastened Roof without Thermal Spacer Blocks

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

Overstated | |

|---|---|---|---|---|---|

|

Single Layer |

R-10 | old | U-0.153 | R-6.5 | 16.8% |

| new | U-0.184 | R-5.4 | |||

| R-11 | old | U-0.139 | R-7.2 | 23.6% | |

| new | U-0.182 | R-5.5 | |||

| R-13 | old | U-0.130 | R-7.7 | 25.3% | |

| new | U-0.174 | R-5.7 | |||

| R-16 | old | U-0.106 | R-9.4 | 32.5% | |

| new | U-0.157 | R-6.4 | |||

| R-19 | old | U-0.098 | R-10.2 | 35.1% | |

| new | U-0.151 | R-6.6 | |||

| Liner System | R11 + R19 | U-0.044 | R-22.7 | N/A |

Table A3.2, Assembly U-factors for Metal Building Walls

Overstated

40.4%

Climate Zone

1-2

Overstated

42.8%

Climate Zone

3 - 4

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

Overstated | |

|---|---|---|---|---|---|

|

Single Layer |

R-6 | old | U-0.184 | R-5.4 | N/A |

| new | N/A | N/A | |||

| R-10 | old | U-0.134 | R-7.4 | 27.9% | |

| new | U-0.186 | R-5.4 | |||

| R-11 | old | U-0.123 | R-8.1 | 33.5% | |

| new | U-0.185 | R-5.4 | |||

| R-13 | old | U-0.113 | R-8.8 | 30.2% | |

| new | U-0.162 | R-6.2 | |||

| R-16 | old | U-0.093 | R-10.7 | 40.4% | |

| new | U-0.155 | R-6.5 | |||

| R-19 | old | U-0.084 | R-11.9 | 42.8% | |

| new | U-0.147 | R-6.8 | |||

|

Double Layer |

R6 + R13 | old | U-0.070 | R-14.2 | N/A |

| new | N/A - See Note Below | ||||

| R10 + R13 | old | U-0.061 | R-16.4 | N/A | |

| new | N/A - See Note Below | ||||

| R13 + R13 | old | U-0.057 | R-17.5 | N/A | |

| new | N/A - See Note Below | ||||

| R19 + R13 | old | U-0.048 | R-20.8 | N/A | |

| new | N/A - See Note Below | ||||

|

Note: Double layer fiberglass wall assemblies were not assigned revised U-Factors and were eventually pulled out, over concerns of constructability and methodology. |

|||||

Metal Building Assembly descriptions

Appendix A

Metal Building Roofs (A2.3)

Describes the metal building roof base assembly as a roof with a thermal spacer block and the insulation is draped perpendicular over the purlins and compressed when the metal roof sheets are installed. It is noted that purlins are spaced nominally 5' on center.

Single Layer (A2.3.2.1)

Refers to a single layer metal building insulation that is laminated with a vapor retarder and is draped perpendicular over purlins and compressed when the roof sheets are attached. Minimum R-3.5 thermal spacer block required when specified in the assembly table A2.3.

![]() Typically known in the metal building industry as 'Over-the-Purlin' method. Learn more about Traditional Methods

Typically known in the metal building industry as 'Over-the-Purlin' method. Learn more about Traditional Methods

Double Layer (A2.3.2.2)

Refers to the second layer of metal building insulation which is unfaced and installed parallel to the purlins and placed on top of the first 'single layer'. Minimum R-3.5 thermal spacer block required when specified in the assembly table A2.3.

![]() This assembly is typically known in the metal building industry as a 'Sag and Bag' method. Although this method features two layers of fiberglass, both layers are still severely compressed and restricted by purlin bracing. Learn more about Traditional Methods

This assembly is typically known in the metal building industry as a 'Sag and Bag' method. Although this method features two layers of fiberglass, both layers are still severely compressed and restricted by purlin bracing. Learn more about Traditional Methods

Continuous Insulation (A2.3.2.3)

Refers to insulation board or blanket which is installed below the purlins and uninterrupted by framing members. The exposed insulation requires a facing and all seams are to be sealed to provide a continuous air barrier.

![]() Continuous insulation installed in metal building roofs, specifically note the placement of the “ci” on the interior, below the purlins.

Continuous insulation installed in metal building roofs, specifically note the placement of the “ci” on the interior, below the purlins.

Continuous Insulation (c.i.) (Section 3, Definitions)

Refers to insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope.

![]() Although continuous insulation's general definition states it can be installed on the interior or exterior; when continuous insulation is installed in metal building roofs, it specifically note the placement of the “ci” on the interior, below the purlins (see A2.3.2.3).

Although continuous insulation's general definition states it can be installed on the interior or exterior; when continuous insulation is installed in metal building roofs, it specifically note the placement of the “ci” on the interior, below the purlins (see A2.3.2.3).

Liner System (Ls) (A2.3.2.4)

Refers to an assembly with the a continuous vapor retarder/membrane that is installed below the purlins and uninterrupted by framing members. Unfaced and uncompressed metal building insulation rests on top of the membrane/liner and is installed parallel between the purlins. Multilayer installations, the first rated Rvalue is for unfaced insulation draped perpendicular over purlins and then compressed when the metal roof sheets are installed. Minimum R-3.5 thermal spacer block required when specified in the assembly table A2.3.

![]() All liner systems listed in 90.1-2010 are multilayer. Most are two layer assemblies with the thicker layer of insulation installed parallel between the purlins and the thin layer is draped perpendicular over the purlin. However, it's important to note that the Standard also lists a three layer Liner system assembly (R11+R11+R25 Ls) in which two layers of uncompressed, unfaced insulation are both installed parallel, between purlins and the thin layer draped perpendicular over the purlin. The Simple Saver System meets the description of the described Liner System. Learn more

All liner systems listed in 90.1-2010 are multilayer. Most are two layer assemblies with the thicker layer of insulation installed parallel between the purlins and the thin layer is draped perpendicular over the purlin. However, it's important to note that the Standard also lists a three layer Liner system assembly (R11+R11+R25 Ls) in which two layers of uncompressed, unfaced insulation are both installed parallel, between purlins and the thin layer draped perpendicular over the purlin. The Simple Saver System meets the description of the described Liner System. Learn more

Liner System (Ls) (Section 3, Definitions)

Refers to an assembly that features a continuous vapor barrier liner installed below the purlins and uninterrupted by framing members.

![]() A more detailed description of a liner system is found in Appendix A. (see A2.3.2.4)

A more detailed description of a liner system is found in Appendix A. (see A2.3.2.4)

Metal Building Walls (A3.2)

Describes the metal building wall base assembly as a wall with metal building insulation compressed between the metal wall panels and the girts. Exposed insulation requires a facing and all seams are to be sealed to provide a continuous air barrier. Girt spacing is not noted.

![]() Girt spacing is not noted in Standard 90.1-2010, however the values are based on girts 7' on center. More information: Traditional Methods

Girt spacing is not noted in Standard 90.1-2010, however the values are based on girts 7' on center. More information: Traditional Methods

Single Layer (A3.2.2.1)

Refers to a single layer of metal building insulation that is laminated with a vapor retarder and is compressed between panels and steel structure.

![]() Typically known in the metal building industry as 'Behind-the-Girt' method. The fiberglass insulation is vertically hung at the top and outside of the building, perpendicular to the girts. The fiberglass insulation is compressed throughout the girt space and severely compressed at the girt/panel fastening point when the metal wall panels are attached. Learn more about Traditional Methods

Typically known in the metal building industry as 'Behind-the-Girt' method. The fiberglass insulation is vertically hung at the top and outside of the building, perpendicular to the girts. The fiberglass insulation is compressed throughout the girt space and severely compressed at the girt/panel fastening point when the metal wall panels are attached. Learn more about Traditional Methods

Double Layer (A3.2.2.2)

Refers to the second layer of faced insulation installed on the interior of building, 'covering' the girts.

![]() It's unclear how this interior layer of faced metal building insulation is installed, however it's clear the girts are covered and not exposed to the interior space. Depending on how the designer, installer, building owner, and/or code official interprets the assembly installation, there may be a large air space between the insulation, inside the girt cavity.

It's unclear how this interior layer of faced metal building insulation is installed, however it's clear the girts are covered and not exposed to the interior space. Depending on how the designer, installer, building owner, and/or code official interprets the assembly installation, there may be a large air space between the insulation, inside the girt cavity.

Continuous Insulation (A3.2.2.3)

Refers to insulation boards installed on the inside of the girts and uninterrupted by framing members.

![]() Although continuous insulation's general definition states it can be installed on the interior or exterior; when continuous insulation is installed in metal building walls, it specifically note the placement of the “ci” on the interior, covering the girts.

Although continuous insulation's general definition states it can be installed on the interior or exterior; when continuous insulation is installed in metal building walls, it specifically note the placement of the “ci” on the interior, covering the girts.

2009 IECC

Prescriptive tables

Table 502.1.2, Building Envelope Requirements Opaque Element, Maximum U-factors (ALL OTHER CRITERIA)

Table 502.2(1), Building Envleope Requirements – Opaque Assemblies (ALL OTHER CRITERIA)

| Climate Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

8

|

|

|---|---|---|---|---|---|---|---|---|---|

|

ASSEMBLY MAXIMUM U-Factor |

Roof | U-0.065 | U-0.055 | U-0.055 | U-0.055 | U-0.055 | U-0.049 | U-0.049 | U-0.035 |

| Wall | U-0.093 | U-0.093 | U-0.084 | U-0.084 | U-0.069 | U-0.069 | U-0.057 | U-0.057 | |

|

ASSEMBLY MINIMUM R-Value |

Roof | R19 | R13+R13 | R13+R13 | R13+R13 | R13+R13 | R13+R19 | R13+R19 | R11+R19 |

| Wall | R16 | R16 | R19 | R19 | R13+R5.6ci | R13+R5.6ci | R19+R5.6ci | R19+R5.6ci | |

|

ci = Continuous insulation |

|||||||||

![]() WARNING! Listed R-value metal building roof and wall assemblies do not perform as the corresponding published U-factor as typically installed. Differences are shown below and further background information can be viewed: ASHRAE Press Release (Jan 12, 2010)

WARNING! Listed R-value metal building roof and wall assemblies do not perform as the corresponding published U-factor as typically installed. Differences are shown below and further background information can be viewed: ASHRAE Press Release (Jan 12, 2010)

![]() The metal building wall U-factors associated with 'hybrid' R-value assemblies feature both fiberglass insulation and continuous insulation are skeptical in the manner it is described in the Standard and in the manner it's “calculated”. The associated U-factor for the hybrid assemblies is calculated by using the U-factor for the installed fiberglass insulation and converting it to the installed R-value (example: Pre-installed R-13 = U-0.113 = Installed R-8.8). The installed R-value of the fiberglass insulation is added to the R-value of the ci increment (R-8.8 + R-5.6ci = R-14.4), then divided by 1 to represent the 'calculated' U-factor of the assembly (1/ R-14.4 = U-0.069).

The metal building wall U-factors associated with 'hybrid' R-value assemblies feature both fiberglass insulation and continuous insulation are skeptical in the manner it is described in the Standard and in the manner it's “calculated”. The associated U-factor for the hybrid assemblies is calculated by using the U-factor for the installed fiberglass insulation and converting it to the installed R-value (example: Pre-installed R-13 = U-0.113 = Installed R-8.8). The installed R-value of the fiberglass insulation is added to the R-value of the ci increment (R-8.8 + R-5.6ci = R-14.4), then divided by 1 to represent the 'calculated' U-factor of the assembly (1/ R-14.4 = U-0.069).

Assembly u-factors

The 2009 IECC does not feature a complete metal building roof and wall assembly list with corresponding installed performance values like ASHRAE Standard 90.1, however it is clear the assemblies are based upon the ASHRAE Tables A2.3 (roofs) and A3.2 (walls). This can be linked by footnote b in Table 502.2(1) Building Envelope Requirements – Opaque Assemblies, whereas the assembly descriptions can be found in the the assembly description Table 502.2(2) which points to specifically ASHRAE 90.1-2007, including addendum “G”.

Assembly Decriptions

Table: 502.2(2), Building Envelope Requirements – Opaque Assemblies

| Roofs | Description | reference |

|---|---|---|

| R-19 |

Standing seam roof with single fiberglass insulation layer. This construction is R-19 faced fiberglass insulation batts draped perpendicular over the purlins. A minimum R-3.5 thermal spacer block is placed above the purlin/batt, and the roof deck is secured to the purlins. |

ASHRAE/IESNA 90.1 Table A2.3 including Addendum “G” |

|

R-13 + R-13 R-13 + R-19 |

Standing seam roof with two fiberglass insulation layers. The first R-value is for faced fiberglass insulation batts draped over purlins. The second R-value is for unfaced fiberglass insulation batts installed parallel to the purlins. A minimum R-3.5 thermal spacer block is placed above the purlin/batt, and the roof deck is secured to the purlins. |

ASHRAE/IESNA 90.1 Table A2.3 including Addendum “G” |

| R-11 + R-19 FC |

Filled cavity fiberglass insulation. A continuous vapor barrier is installed below the purlins and uninterrupted by framing members. Both layers of uncompressed, unfaced fiberglass insulation rest on top of the vapor barrier and are installed parallel, between the purlins. A minimum R-3.5 thermal spacer block is placed above the purlin/batt, and the roof deck is secured to the purlins. |

ASHRAE/IESNA 90.1 Table A2.3 including Addendum “G” |

| Walls | Description | reference |

|---|---|---|

| R-16, R-19 |

Single fiberglass insulation layer. The construction is faced fiberglass insulation batts installed vertically and compressed between the metal wall panels and the steel framing. |

ASHRAE/IESNA 90.1 Table A2.3 including Addendum “G” |

|

R-13 + R-5.6ci R-19 + R-5.6ci |

The first R-value is for faced fiberglass insulation batts installed perpendicular and compressed between the metal wall panels and the steel framing. The second rated R-value is for continuous rigid insulation installed between the metal wall panel and steel framing, or on the interior of the steel framing. |

ASHRAE/IESNA 90.1 Table A2.3 including Addendum “G” |

90.1-2007

Prescriptive tables

5.5-1 thru 5.5-8, Metal Building Envelope Requirements (NONRESIDENTIAL CRITERIA)

| Climate Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

|

ASSEMBLY MAXIMUM U-Factor |

Roof | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.049 |

| Wall | U-0.113 | U-0.113 | U-0.113 | U-0.113 | U-0.113 | U-0.113 | U-0.057 | U-0.057 | |

|

ASSEMBLY MINIMUM R-Value |

Roof | R19 | R19 | R19 | R19 | R19 | R19 | R19 | R13+R19 |

| Wall | R13 | R13 | R13 | R13 | R13 | R13 | R13+R13 | R13+R13 | |

![]() WARNING! Listed R-value metal building roof and wall assemblies do not perform as the corresponding published U-factor as typically installed. Differences (OLD/NEW) are shown below in Table A2.3 and Table A3.2. Further background information can be viewed: ASHRAE Press Release (Jan 12, 2010)

WARNING! Listed R-value metal building roof and wall assemblies do not perform as the corresponding published U-factor as typically installed. Differences (OLD/NEW) are shown below in Table A2.3 and Table A3.2. Further background information can be viewed: ASHRAE Press Release (Jan 12, 2010)

![]() The metal building wall U-factor (U-0.057) associated with double layer of R13+R13 fiberglass insulation is skeptical in the manner it is described in the Standard and in the manner it's “calculated”. The associated U-factor was calculated by using the U-factor for the installed fiberglass insulation and converting it to the installed R-value (example: Pre-installed R-13 = U-0.113 = Installed R-8.8). The installed R-value of the fiberglass insulation is added together (R-8.8 + R-8.8 = R-17.6), then divided by 1 to represent the 'calculated' U-factor of the assembly (1/ R-17.6 = U-0.057).

The metal building wall U-factor (U-0.057) associated with double layer of R13+R13 fiberglass insulation is skeptical in the manner it is described in the Standard and in the manner it's “calculated”. The associated U-factor was calculated by using the U-factor for the installed fiberglass insulation and converting it to the installed R-value (example: Pre-installed R-13 = U-0.113 = Installed R-8.8). The installed R-value of the fiberglass insulation is added together (R-8.8 + R-8.8 = R-17.6), then divided by 1 to represent the 'calculated' U-factor of the assembly (1/ R-17.6 = U-0.057).

Assembly u-factors

Table A2.3, Assembly U-factors for Metal Building Roofs

Standing Seam Roof with Thermal Spacer Blocks

Overstated

20.7%

Climate Zone

1 - 7

Overstated

27.9%

Climate Zone

8

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

Overstated | |

|---|---|---|---|---|---|

| SINGLE LAYER | R-6 | old | U-0.167 | R-5.9 | N/A |

| new | N/A | N/A | |||

| R-10 | old | U-0.097 | R-10.3 | 15.7% | |

| new | U-0.115 | R-8.7 | |||

| R-11 | old | U-0.092 | R-10.8 | 14.0% | |

| new | U-0.107 | R-9.3 | |||

| R-13 | old | U-0.083 | R-12.0 | 17.8% | |

| new | U-0.101 | R-9.9 | |||

| R-16 | old | U-0.072 | R-13.9 | 25.0% | |

| new | U-0.096 | R-10.4 | |||

| R-19 | old | U-0.065 | R-15.4 | 20.7% | |

| new | U-0.082 | R-12.2 | |||

|

DOUBLE LAYER |

R10 + R10 | old | U-0.063 | R-15.8 | 28.4% |

| new | U-0.088 | R-11.4 | |||

| R10 + R11 | old | U-0.061 | R-16.4 | 29.1% | |

| new | U-0.086 | R-11.6 | |||

| R11 + R11 | old | U-0.060 | R-16.6 | 29.4% | |

| new | U-0.085 | R-11.8 | |||

| R10 + R13 | old | U-0.058 | R-17.2 | 31.0% | |

| new | U-0.084 | R-11.9 | |||

| R11 + R13 | old | U-0.057 | R-17.5 | 30.5% | |

| new | U-0.082 | R-12.2 | |||

| R13 + R13 | old | U-0.055 | R-18.1 | 26.7% | |

| new | U-0.075 | R-13.3 | |||

| R10 + R19 | old | U-0.052 | R-19.2 | 29.7% | |

| new | U-0.074 | R-13.5 | |||

| R11 + R19 | old | U-0.051 | R-19.6 | 29.2% | |

| new | U-0.072 | R13.9 | |||

| R13 + R19 | old | U-0.049 | R-20.4 | 27.9% | |

| new | U-0.068 | R-14.7 | |||

| R16 + R19 | old | U-0.047 | R-21.2 | 27.7% | |

| new | U-0.065 | R-15.4 | |||

| R19 + R19 | old | U-0.046 | R-21.7 | 23.3% | |

| new | U-0.060 | R-16.7 | |||

| FILLED CAVITY | R19 + R10 | U-0.041 | R-24.4 | N/A |

Thru-Fastened Roof without Thermal Spacer Blocks

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

Overstated | |

|---|---|---|---|---|---|

| SINGLE LAYER | R-10 | old | U-0.153 | R-6.5 | 16.8% |

| new | U-0.184 | R-5.4 | |||

| R-11 | old | U-0.139 | R-7.2 | 23.6% | |

| new | U-0.182 | R-5.5 | |||

| R-13 | old | U-0.130 | R-7.7 | 25.3% | |

| new | U-0.174 | R-5.7 | |||

| R-16 | old | U-0.106 | R-9.4 | 32.5% | |

| new | U-0.157 | R-6.4 | |||

| R-19 | old | U-0.098 | R-10.2 | 35.1% | |

| new | U-0.151 | R-6.6 |

Table A3.2, Assembly U-factors for Metal Building Walls

Overstated

30.2%

Climate Zone

1 - 6

Overstated

28.8%

Climate Zone

7-8

|

Insulation Assembly |

Pre-Installed R-value |

Assembly U-factor |

Installed R-value |

Overstated | |

|---|---|---|---|---|---|

| SINGLE LAYER | R-6 | old | U-0.184 | R-5.4 | N/A |

| new | N/A | N/A | |||

| R-10 | old | U-0.134 | R-7.4 | 27.9% | |

| new | U-0.186 | R-5.4 | |||

| R-11 | old | U-0.123 | R-8.1 | 33.5% | |

| new | U-0.185 | R-5.4 | |||

| R-13 | old | U-0.113 | R-8.8 | 30.2% | |

| new | U-0.162 | R-6.2 | |||

| DOUBLE LAYER | R6 + R13 | old | U-0.070 | R-14.2 | N/A |

| new | N/A - See Note Below | ||||

| R10 + R13 | old | U-0.061 | R-16.4 | N/A | |

| new | N/A - See Note Below | ||||

| R13 + R13 | old | U-0.057 | R-17.5 | N/A | |

| new | N/A - See Note Below | ||||

| R19 + R13 | old | U-0.048 | R-20.8 | N/A | |

| new | N/A - See Note Below | ||||

|

Note: Double layer fiberglass wall assemblies were not assigned revised U-Factors and were eventually pulled out, over concerns of constructability and methodology. |

|||||

Metal Building Assembly descriptions

Appendix A

Metal Building Roofs (A2.3)

Describes the metal building roof base assembly as a roof with insulation draped perpendicular, over the purlins and compressed when the metal roof sheets are installed. Purlin spacing is not noted.

Single Layer (A2.3.2.1)

Refers to a single layer metal building insulation that is laminated with a vapor retarder and is draped perpendicular over purlins and compressed when the roof sheets are attached. Minimum 1” thermal spacer block required when specified in the assembly table A2.3.

![]() Typically known in the metal building industry as 'Over-the-Purlin' method. More information: Traditional Methods

Typically known in the metal building industry as 'Over-the-Purlin' method. More information: Traditional Methods

Double Layer (A2.3.2.2)

Refers to the second layer of metal building insulation which is unfaced and installed parallel to the purlins and placed on top of the first 'single layer'. Minimum 1” thermal spacer block required when specified in the assembly table A2.3.

![]() This assembly is typically known in the metal building industry as a 'Sag and Bag' method. Although this method features two layers of fiberglass, both layers are still severely compressed and restricted by purlin bracing. More information: Traditional Methods

This assembly is typically known in the metal building industry as a 'Sag and Bag' method. Although this method features two layers of fiberglass, both layers are still severely compressed and restricted by purlin bracing. More information: Traditional Methods

Continuous Insulation (A2.3.2.3)

Refers to insulation board or blanket insulation which is installed below the purlins and uninterrupted by framing members (purlins). The exposed insulation requires a facing and all seams are to be sealed to provide a continuous air barrier.

![]() Continuous insulation installed in metal building roofs, specifically note the placement of the “ci” on the interior, below the purlins.

Continuous insulation installed in metal building roofs, specifically note the placement of the “ci” on the interior, below the purlins.

Continuous Insulation (c.i.) (Section 3, Definitions)

Refers to insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope.

![]() Although continuous insulation's general definition states it can be installed on the interior or exterior; when continuous insulation is installed in metal building roofs, it specifically note the placement of the “ci” on the interior, below the purlins (see A2.3.2.3).

Although continuous insulation's general definition states it can be installed on the interior or exterior; when continuous insulation is installed in metal building roofs, it specifically note the placement of the “ci” on the interior, below the purlins (see A2.3.2.3).

Metal Building Walls (A3.2)

Describes the metal building wall base assembly as a wall with metal building insulation compressed between the metal wall panels and the girts. Exposed insulation requires a facing and all seams are to be sealed to provide a continuous air barrier. Girt spacing is not noted.

![]() Girt spacing is not noted in Standard 90.1-2007, however the values are based on 7' on center. More information: Traditional Methods

Girt spacing is not noted in Standard 90.1-2007, however the values are based on 7' on center. More information: Traditional Methods

Single Layer (A3.2.2.1)

Refers to a single layer of metal building insulation that is laminated with a vapor retarder and is compressed between panels and steel structure.

![]() Typically known in the metal building industry as 'Behind-the-Girt' method. The fiberglass insulation is vertically hung at the top and outside of the building, perpendicular to the girts. The fiberglass insulation is compressed throughout the girt space and severely compressed at the girt/panel fastening point when the metal wall panels are attached. More information: Traditional Methods

Typically known in the metal building industry as 'Behind-the-Girt' method. The fiberglass insulation is vertically hung at the top and outside of the building, perpendicular to the girts. The fiberglass insulation is compressed throughout the girt space and severely compressed at the girt/panel fastening point when the metal wall panels are attached. More information: Traditional Methods

Double Layer (A3.2.2.2)

Refers to the second layer of faced insulation installed on the interior of building, 'covering' the girts.

![]() It's unclear how this interior layer of faced metal building insulation is installed, however it's clear the girts are covered and not exposed to the interior space. Depending on how the designer, installer, building owner, and/or code official interprets the assembly installation, there may be a large air space between the insulation, inside the girt cavity.

It's unclear how this interior layer of faced metal building insulation is installed, however it's clear the girts are covered and not exposed to the interior space. Depending on how the designer, installer, building owner, and/or code official interprets the assembly installation, there may be a large air space between the insulation, inside the girt cavity.

Continuous Insulation (A3.2.2.3)

Refers to insulation boards installed on the inside of the girts and uninterrupted by framing members.

![]() Although continuous insulation's general definition states it can be installed on the interior or exterior; when continuous insulation is installed in metal building walls, it specifically note the placement of the “ci” on the interior, covering the girts.

Although continuous insulation's general definition states it can be installed on the interior or exterior; when continuous insulation is installed in metal building walls, it specifically note the placement of the “ci” on the interior, covering the girts.

2006 IECC

Prescriptive tables

Table 502.2(1), Building Envelope Requirements – Opaque Assemblies

TABLE 502.1.2, BUILDING ENVELOPE REQUIREMENTS – OPAQUE Element, Maximum u-factors (2007 Supplement)

| Climate Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

|

ASSEMBLY MAXIMUM U-Factor |

Roof | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.049 |

| Wall | U-0.113 | U-0.113 | U-0.113 | U-0.113 | U-0.113 | U-0.113 | U-0.057 | U-0.057 | |

|

ASSEMBLY MINIMUM R-Value |

Roof | R19 | R19 | R19 | R19 | R19 | R19 | R19 | R13+R19 |

| Wall | R13 | R13 | R13 | R13 | R13 | R13 | R13+R13 | R13+R13 | |

Assembly U-factors

The 2006 IECC does not list U-factors within the energy code however are linked and referenced by footnote b in Table 502.2(1) Building Envelope Requirements – Opaque Assemblies, whereas the assembly descriptions can be found in the the assembly description Table 502.2(2) which points to specifically ASHRAE 90.1 (with reference document Standard 90.1-2004).

![]() The IECC did not publish metal building roof and wall U-factors until the release of their 2007 Supplement when it added Table 502.1.2, Building Envelope Requirements – Opaque Element, Maximum U-factors.

The IECC did not publish metal building roof and wall U-factors until the release of their 2007 Supplement when it added Table 502.1.2, Building Envelope Requirements – Opaque Element, Maximum U-factors.

Assembly Decriptions

Table: 502.2(2), Building Envelope Requirements – Opaque Assemblies

| Roofs | Description | reference |

|---|---|---|

| R-19 + R-10 |

Filled cavity roof. Thermal blocks are a minimum, R-5 of rigid insulation, which extends 1 in. beyond the width of the purlin on each side, perpendicular to the purlin. This construction is R-10 insulation batt sdraped perpendicularly over the purlins, with enough looseness to allow R-19 batt to be laid above it, parallel to the purlins. Thermal blocks are then placed above the purlin/batt, and the roof deck is secured to the purlins |

ASHRAE/IESNA 90.1 Table A2.3 |

| R-19 |

Thermal blocks are a minimum, R-5 of rigid insulation, which extends 1 in. beyond the width of the purlin on each side, perpendicular to the purlin. This construction is R-19 insulation batts draped perpendicular over the purlins. Thermal blocks are then placed above the purlin/batt, and the roof deck is secured to the purlins. |

ASHRAE/IESNA 90.1 Table A2.3 |

| Walls | Description | reference |

|---|---|---|

| R-13 |

Single insulation layer. The first layer of R-13 insulation batts is installed continuously perpendicular to the girts and is compressed as the metal skin is attached to the girts. |

ASHRAE/IESNA 90.1 Table A2.3 |

| R-13 + R-13 | The first layer of R-13 insulation batts is installed continuously perpendicular to the girts and is compressed as the metal skin is attached to the girts. The second layer of R-13 insulation batts is installed within the framing cavity. |

ASHRAE/IESNA 90.1 Table A2.3 |

90.1-2004

Prescriptive tables

5.5-1 thru 5.5-8, Metal Building Envelope Requirements (NONRESIDENTIAL CRITERIA)

| Climate Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

|

ASSEMBLY MAXIMUM U-Factor |

Roof | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.065 | U-0.049 |

| Wall | U-0.113 | U-0.113 | U-0.113 | U-0.113 | U-0.113 | U-0.113 | U-0.057 | U-0.057 | |

|

ASSEMBLY MINIMUM R-Value |

Roof | R19 | R19 | R19 | R19 | R19 | R19 | R19 | R13+R19 |

| Wall | R13 | R13 | R13 | R13 | R13 | R13 | R13+R13 | R13+R13 | |

![]() WARNING! Listed R-value metal building roof and wall assemblies do not perform as the corresponding published U-factor as typically installed. Differences (OLD/NEW) are shown below in Table A2.3 and Table A3.2. Further background information can be viewed: ASHRAE Press Release (Jan 12, 2010)

WARNING! Listed R-value metal building roof and wall assemblies do not perform as the corresponding published U-factor as typically installed. Differences (OLD/NEW) are shown below in Table A2.3 and Table A3.2. Further background information can be viewed: ASHRAE Press Release (Jan 12, 2010)